Everyone has their opinion on which feed pan is the best feed pan. It creates a loyalty that is hard to shake, even in the face of evidence of something better.

The reality is that it’s really hard to know what makes a great feed pan, because there are so many shared features. For instance, most pans are plastic. Manufacturers switched to plastics in the 80’s, partly because they were cheaper to manufacture and ship, but also because they allow for significantly increased longevity in the abrasive environment of a poultry house. Plastics are nonporous and noncorrosive; bacteria and viruses are easily washed away and the harsh cleaning agents won’t degrade the equipment.

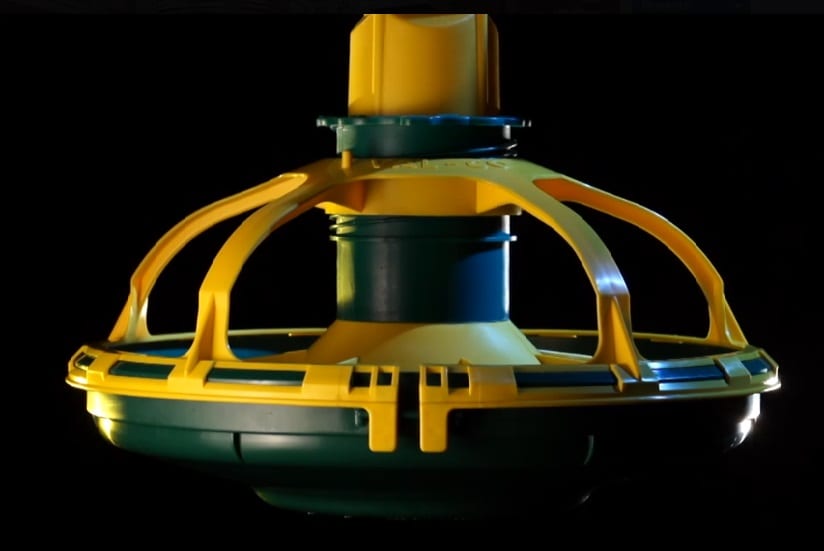

But not all plastics are created equal. You might still assume that “lightweight” does not equal “durable”. More plastic used to indicate tougher pans, but today’s modern, lightweight polymers have changed the equation. Now, heavier pans mean you’re probably paying for more plastic that doesn’t influence the performance of the flock or increase the longevity of the pans.

Most pans have grills. The number of spokes or dividers on each grill varies from one model to the next. Some have four spokes, some have 14. Ultimately, the number of spokes really just dictates how many birds have access to the pan at a given time. Open grills allow more useable feed space, but require closer management to control feed wastage. More spokes will limit useable feed space but minimize birds’ side-to-side movement preventing them from flicking feed outside the pan.

“But all the grills are shaped differently, too.” Well, sure. Manufacturers need to make sure birds have enough clearance to move their heads around to eat. Since birds can’t swallow well, they can’t eat with their heads down, and so must lift their heads often. Plus, chicks like to hop in the pan and move around when they eat, so the grills must be high enough that brooding chicks won’t get stuck, and low enough that, as the birds grow, they can no longer fit in the pan because the grill is in the way.

“But all the grills are shaped differently, too.” Well, sure. Manufacturers need to make sure birds have enough clearance to move their heads around to eat. Since birds can’t swallow well, they can’t eat with their heads down, and so must lift their heads often. Plus, chicks like to hop in the pan and move around when they eat, so the grills must be high enough that brooding chicks won’t get stuck, and low enough that, as the birds grow, they can no longer fit in the pan because the grill is in the way.

“Speaking of the pan, why are they all different depths?” Again, grower preference. Brooding chicks need to learn how to eat from the pan, and they start to learn early on in the rearing period. If you grow on slatted floors or in shallow litter, you might prefer a shallow pan – its low feed lip will give chicks better access to feed. However, if mismanaged, there may be more feed wastage because the feed is closer to the lip of the pan and easier to flick out. Standard and shallow pans hold the same amount of feed, but the higher feed lip of the standard pan often results in less feed waste from this flicking behavior.

If spillage seems to be a problem, its often a problem with the settings allowing too much feed to be present in the pan. Flooding is good for chicks, but during grow out, lower settings will help control the feed levels.

“If every pan has the same features, how do I know I have the best option?”

Look at your management style. The type of barn, integrator requirements, litter depth and material, feed type and breed of bird are all factors in choosing the best feeder for your operation. Ultimately, proof of performance will be in your feed conversion and livability numbers, assuming all other factors are neutral.

We’ve spent A LOT of time considering all the design elements of a really good feed pan, and we feel really good about what we’ve designed into the FUZE ProLine feeders.

We’ve outperformed our competition in integrator-led feed trials across both summer and winter flocks. We’ve replaced pans in grower houses that were finishing dead last, and helped them finish at worst, in the middle; at best, they finished top 3.

So as much as you might think a pan is a pan is a pan, a pan is much more. A pan is high-quality plastics, careful design, extensive testing, and keen management.