Forced air heaters have largely become obsolete in poultry houses as producers have switched to brooders and tube heaters. These radiant heating options deliver heat directly to the floor and the birds at a much more affordable rate. Radiant heaters are significantly more efficient, offer drier litter, and create a heat-storing reservoir for the birds at floor level. These also offer varying temperature gradients, so birds can find their own thermal comfort zones.

Forced air heaters have largely become obsolete in poultry houses as producers have switched to brooders and tube heaters. These radiant heating options deliver heat directly to the floor and the birds at a much more affordable rate. Radiant heaters are significantly more efficient, offer drier litter, and create a heat-storing reservoir for the birds at floor level. These also offer varying temperature gradients, so birds can find their own thermal comfort zones.

There are three main styles in the industry: brooders, tube heaters, and U-tube heaters. Each style offers a different heating pattern. These patterns can inform the style of radiant heater a producer chooses for their farm.

It’s important to remember that each facility requires a heat loss calculation to determine the actual Btu/hour that is needed to warm the floors and the house. This is dependent on house tightness and insulation, which should be checked annually for efficiency.

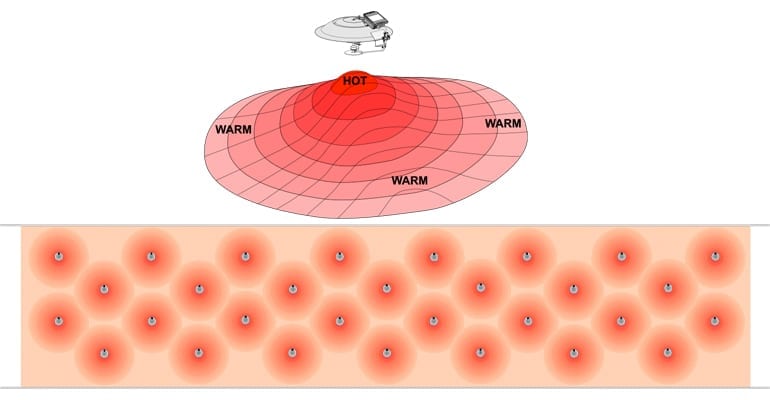

Radiant Brooders:

Radiant brooders are open flame heating systems that have a visible flame and the air for combustion comes from within the building. Because of this, they often get dust and debris in all the components and will need to be cleaned after every flock.

They are comprised of a canopy, an emitter, and a burner as the most critical components. The circular canopies reflect the heat to the litter and the chicks, and lose some to the ambient air. The emitter is heated by combustible gas and “emits” radiant heat to the litter.

Brooders are available with either pilot or direct spark ignitions. Direct spark ignitions use a high voltage electrical arc between two electrodes to light gas flowing to the burner. These models can save approximately 1500-2000 Btu/hour when the house is not in need of supplemental heat.

The round heating pattern means more are required to cover an area, though this style commonly has a lower upfront cost, and so are a popular choice. Brooders are usually installed over feeding and watering lines to encourage birds to eat and drink. They hang closer to the floors and therefore must be raised and lowered during use. Winching them to different heights during the flock will change the heating pattern and intensity.

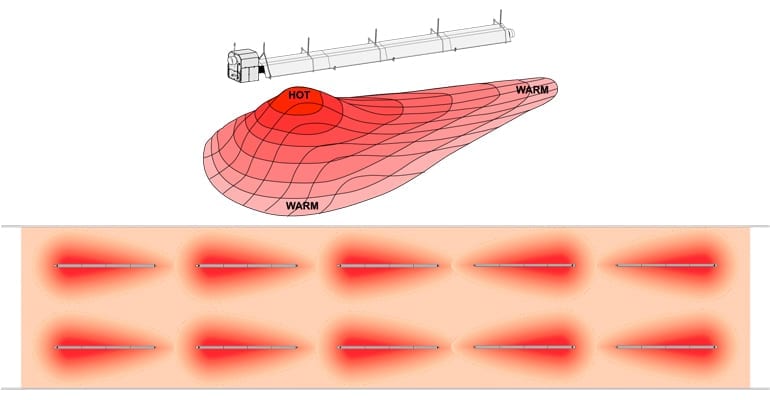

Radiant tube heat:

Tube heaters are closed-flame heating systems that frequently source combustion air from outside the house and enclose the flame in a box, connected to a tube. A fan forces hot combustion gases through the tube which radiates heat to the litter. Because the combustion air can come from outside, these usually require less maintenance.

Tube heaters are closed-flame heating systems that frequently source combustion air from outside the house and enclose the flame in a box, connected to a tube. A fan forces hot combustion gases through the tube which radiates heat to the litter. Because the combustion air can come from outside, these usually require less maintenance.

Tube heaters create a large pear-shaped heat profile, where the warmest temperatures are under the heating box end and the lower temperatures are at the far end of the tube. The higher heat capacity and wider radiant spread mean heaters are installed nearer to the ceiling and do not have to be raised and lowered.

The mounting height and reflector geometry determine the width of the heat distribution on the floor and the more diverse temperature gradients allow birds to find their own thermal comfort zone.

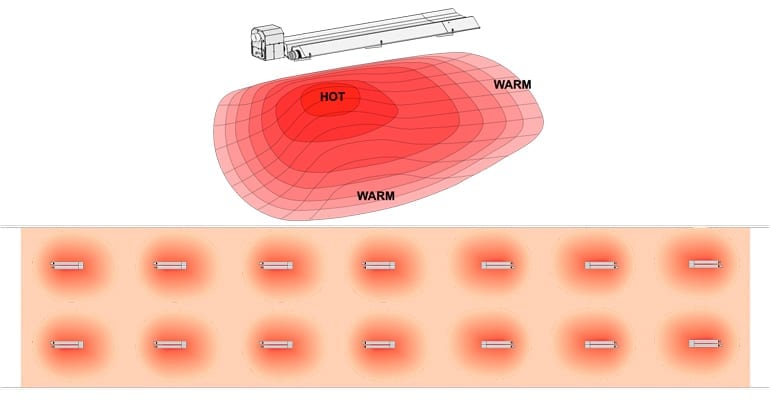

U-Tube heaters:

U-tube heaters have all the same properties as straight tube heaters, though the tube curves back around and the reflectors are angled in a “V” shape. These are shorter than straight tubes and create a more even, rectangular heat pattern. The heat input is lower, so the hotspot under the burner is less intense, but more are needed to cover the same amount of barn space versus a standard straight tube heater.

Regardless of the heater that’s used, careful observation of the birds is the best way to determine their comfort. Birds huddled together under lights are too cold, and often crowding near the side walls indicates they are too hot. Make adjustments as needed.

Photo and info sources:

Choose the Right Heater for Poultry Brooding by Paul Horne

Subscribe to our blog!