There are several types of ventilation options that can be used, some more common than others. In the US, where the majority of pig production is done in just a handful of states, all of which suffer cold, blustery winters, negative pressure ventilation is the most common system. In areas where climate is more temperate, natural ventilation – allowing air exchange to be powered by buoyancy and wind – may be the way to go. These practices have been in use for quite some time, but there are some up and coming trends in swine housing ventilation, which include positive pressure systems, and neutral pressure (push-pull) systems, that may be better for the pigs, and better for your wallet.

There are several types of ventilation options that can be used, some more common than others. In the US, where the majority of pig production is done in just a handful of states, all of which suffer cold, blustery winters, negative pressure ventilation is the most common system. In areas where climate is more temperate, natural ventilation – allowing air exchange to be powered by buoyancy and wind – may be the way to go. These practices have been in use for quite some time, but there are some up and coming trends in swine housing ventilation, which include positive pressure systems, and neutral pressure (push-pull) systems, that may be better for the pigs, and better for your wallet.

The most important concept to keep in mind when talking about ventilation is static pressure. It’s basic, but it’s important. Static pressure is the pressure inside the building compared to the outside of the building.

We talk about this most commonly when talking about negative pressure ventilation – the pressure inside the house drops when the exhaust fans turn on, and this creates a vacuum that pulls air into the barn through the inlets. Conversely, static pressure also applies when discussing positive pressure. The fans push the air into the house, raising the pressure inside, and which pushes the air out through the inlets. In a neutral, or push-pull, system, the pressure stays at approximate zero, so the fans work together to both push air into the house, and out of it.

No (mechanical) ventilation is possible without fans, and choosing the right one can be tricky. They are rated in terms of cubic feet of air per minute (cfm) but how many fans do you actually need? Depends on your barn size and herd size. A few simple calculations will help us choose the right fan.

- Determine the minimum ventilation rate (W)

- Determine the maximum ventilation rate (S)

- Determine two intermediate ventilation rates ( I1 & I2)

Step One:

The minimum ventilation rate is used to maintain air quality and humidity while minimizing heat loss during cold weather.

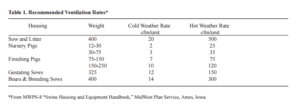

(W) in cfm = # of animals X cold weather rate (cfm/animal)

Step Two:

*These guidelines are from the mid-80’s and with today’s high-performing genetics we frequently see people increasing the maximum Hot Weather Rate by 10-20% for Farrowing and Finishers.

The maximum ventilation rate is the highest practical rate for hot weather conditions.

(S) in cfm = # of animals X hot weather rate (cfm/animal)

Step Three:

Each system should have at least four ventilation stages, which means we have to determine some intermediate stages.

(I1) in cfm = [(S) – (W) / (#of stages + 2)] + (W)

(I2) in cfm = [2 X {(S) – (W)} / (# of stages + 2)] + I1

Once we’ve determined what the cfm requirements are in each stage, we can find a fan that provides the proper rate at each stage.

Minimum ventilation fan = (W)

Second stage fan = (I1 – (W)

Third stage fan = (I2) – (I1)

Maximum ventilation fan = (S) – (I2)

Using static pressure ratings of 0.125 or 0.1 inches of water is recommended for selecting winter fans (stages W and I1). Static pressure ratings of 0.05 to 0.08 inches of water may be used for summer fans (stages I2 and S).

Fan test data is examined to find fans that are available that meet the calculated size requirement. Fan test data is available from the Air Movement and Control Association (AMCA) or from the Bioenvironmental and Structural Systems Laboratory (BESS) at the University of Illinois.

Want to check out our fan selection? Hop on over! Or come check them out in person at the World Pork Expo in Booth V 639!