Management Minute – Broiler Weight Monitoring

Broiler weight is an important parameter when growing broilers. After all, the end goal of raising broilers is to get as many birds to market as possible, using the least amount of feed, and producing the greatest amount of meat. With pressures on the industry to reduce antibiotic usage, there is a greater focus on finding new ways to maximize birds’ growth, health, and well being from the earliest stages.

Broiler weight is an important parameter when growing broilers. After all, the end goal of raising broilers is to get as many birds to market as possible, using the least amount of feed, and producing the greatest amount of meat. With pressures on the industry to reduce antibiotic usage, there is a greater focus on finding new ways to maximize birds’ growth, health, and well being from the earliest stages.

It has long been known that the better start a broiler bird gets the better chance for that bird to reach its genetic potential. Broiler chickens have the genetic potential for significant weight gain over a very short period of time. During the first 7 days, 80% of the bird’s energy is used for growth and only 20% for maintenance, indicating the importance of this period in the chicken’s life. Weighing around 42g at hatch, broilers can achieve a weight of 2,800g (6 lbs.) within the next 42 days – an average daily growth rate of 66g (.146 lbs.). This growth rate is particularly significant within the first seven days, as the bird has the potential to increase its body weight by 450% from day zero to day seven. Furthermore, according to management guidelines for the modern broiler, the birds are supposed to increase their live weight 4.25 times during the first 7 days, from approximately 40g to 180g. Seven-day weight of the Cobb 500 in comparison with hatch weight has increased by 300% over the last 20 years.

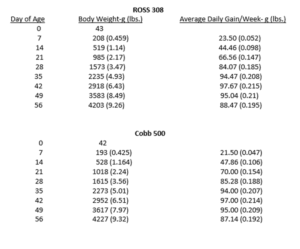

Good early development of the chick reaching high 7-day weights will have a significant positive impact on the bird for the rest of its life. It will improve the nutritional maturity of the bird and accelerate development of the gastro- intestinal tract. Muscle growth and development of muscle morphology improves, as will long-term positive metabolic effects. Below are performance numbers published by Ross and Cobb as to what should be expected for weight gains on their straight run broilers.

As important as bird weight is in the broiler industry, it has never been a common practice to routinely weigh broilers, mainly due to the physical time it takes to weigh birds on a multiple barn farm. With the development of accurate automatic scales that can have multiple platforms in a single barn, collecting weights on a broiler farm has become easier, whether you raise straight run birds or sexed birds. Actively weighing your birds gives vital data to help better manage birds to reach their genetic potential. Weighing broilers can confirm how effective different management practices are. Why spend time and energy doing something that does not give a payback in performance?

Every management technique implemented should be to maximize performance of the flock. There are weighing systems available with computer software that will collect and calculate important data such as average daily weight gains, daily actual weight, coefficient of variation, uniformity, and number of birds weighed. Some programs have built in breed weight curves to be able to easily compare gains with documented weight curves for specific breeds. These programs can have mortality inputted to be able to track total mortality easily. Some of these programs will create graphs, email information, and send information to Excel spreadsheets which allows past flocks to be stored for easy comparison.

One of the best technological advancements for these weighing systems is the ability to be monitored through a controller or the internet. These systems allow the user to access their information from an offsite location over the internet or just view and collect the data at a central location on the farm. A production data analysis can help determine which flocks are meeting their genetic potential and which flocks are not, as well as which management practices are beneficial.

As weights are collected, if the weights of the flock are not following the recommended breed guidelines, an investigation can begin to determine the cause, instead of waiting until the flock ships only to learn the flock has below average weight gain. Some of the problems that could be discovered to cause poor weight gain include disease challenges, temperature or air quality issues, inadequate feed space for all birds to eat (birds not evenly spaced throughout barn), slow feed delivery or distribution, and feed formulation or quality problems. By catching a problem early, it is possible to get the birds back on track, maybe not completely recover but at least work to get the birds back on their growth curve and maximize remaining growth days.

The success of any poultry program must be driven with data. Good decision-making is dependent upon the quality of data and ensuring that the numbers are accurate and complete. The level of uniformity largely contributes to the final result, and as with any business, increasing profits with positive final results is what one is after. The broiler industry is no different. Invest in a tool to maximize performance and profits.

Matt Murray

Tech Support

Subscribe to our blog!