Fan maintenance for efficient ventilation

Now that the warmer weather is upon us and temperatures are dictating the ramping up of our ventilation stages, it is a great time to check a few easy wear points of our barn fans to make sure they are still working at the efficiency we expect and count on.

First things first, always make sure your fan shutters/grill aren’t being choked by an excessive accumulation of dust and feathers that if severe can rob you of over 30% fan performance. By removing the internal shutter, after locking and tagging out the fan being worked on, the main components to your fans should be front and center to investigate. The first thing you should notice is your belt and how exactly it is riding in the pulley channels. Belt and pulley wear is common and if not kept after, can drop fan efficiency by 20%!

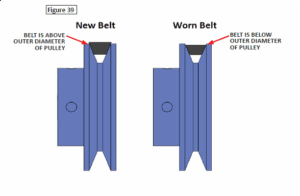

Belt wear is common and looks like the picture at right:

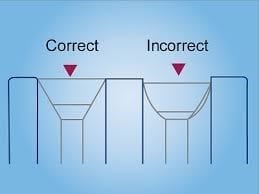

Once the belt begins to ride the groove of the pulley lower than the outer diameter of the groove, it is time to replace the belt. A common cause of belt wear would be when the motor pulley is out of square with the auto tensioning pulley. This will cause lopsided wearing on the belt, decrease the lifespan of the belt, and hurt fan efficiency overall. If the v-channel of the pulley has a metallic sheen and becomes more rounded than triangular, it is time to replace the pulley.

All VAL-CO fans are rated to certain static pressures (CFM data is on all fan literature on our website). At low static pressures, .05”, when a fan is rotating 10% slower than usual, fan air volume is reduced 5-10%. When operating at increased static pressures, for instance .15”, air capacity is reduced 10-20% when the propeller is spinning 10% slower than its supposed to. If the propeller speed drops by 20%, your air volume can be 40% less than what you’re are counting on for bird heat removal![1]

After the belt, pulleys, and bearings are checked, the next thing would be the motor itself. One easy way to test the motor/propeller performance is with a cheap tachometer. By shooting the fan blades in use, you can see the speed of the propeller and compare this number to the fans tested metric, http://bess.illinois.edu/search.asp, under the current house static pressure. If the numbers don’t line up, it may be time to replace your fan motor.

All in all, this is a great time of year to go through your barn and check your fans for performance issues before the weather gets too warm and your barn efficiency suffers.

[1] Michael Czarick, UGA Poultry Housing Tips, House Temp and Fan Maintenance, Vol 30, Num 4, 2018