Water is arguably the most important element to consider when operating a poultry farm. It keeps birds hydrated, it encourages them to eat and is essential for the digestion of what they do eat, and it acts as an administration tool to deliver medications and supplements to keep them healthy. It is the essential solvent for life as we know it; it’s practically a miracle formula. Here’s the catch: if it’s not clean, it’s not a miracle formula.

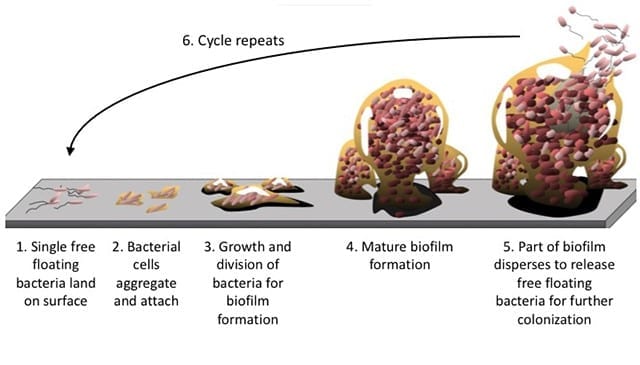

It’s necessary to clear the water lines of contaminants like bacteria, sludge, drug residues, and mineral buildup on a regular basis. Otherwise, you get a frustrating thing called biofilm. What’s biofilm? Biofilm is a collection of bacteria and other organisms that live together in a sticky film inside the pipes, regulators, and nipple drinkers. It protects itself with a mucous membrane (better known as slime) that neutralizes cleaners, and as it grows and spreads, it releases bacteria into the water that your birds are drinking.

What kind of bacteria are they drinking? E. coli. Salmonella. Bordatella.

All of these, and others not listed, potentially lead to mortality, reduced efficiencies, health issues, and loss of revenue.

Who should clean their water lines?

- Anyone using a well.

- Anyone using a public water source.

- Anyone using a natural water source like a pond or lake.

Really, anyone in animal production should be sure that their water is clean. What the water carries, the animals will consume.

Image: Stages of Biofilm Development; bayarealyme 2015

When should water lines be cleaned?

This varies with initial water quality, but as a baseline:

- At least every 4 months.

- Always between flocks.

- And a daily sanitation program could prove beneficial to make more thorough cleanings more effective.

Biofilms can re-emerge in as little as 2-3 days if the conditions are right, so doing a thorough deep clean in conjunction with a daily sanitation program will ensure that the water is always safe to drink. Flush weekly to remove particles that could be affecting the flow of water, and flush after the administration of any medications or supplements.

What should you use to clean the water lines?

There are several options, some more effective than others. Their effectiveness will depend on your water quality and content, so you should first know your source, and the baseline of the dissolved solids in your water. These substances can include phosphorus, sulfates, nitrates, sodium, chloride, iron, magnesium, manganese, and calcium.

Chlorine: Chlorine is not the best choice for areas where chloride levels are already high, as too much chlorine in the water will back birds off from drinking and damage the system. Chlorine solutions work best in pH 4 to 7. You must have the proper level of chlorine at the end of the water line farthest from the water source to ensure that chlorine is doing its job. You should have 3 to 5 ppm of free chlorine at the end of the line for your sanitation program to be effective. More than 5 ppm may be too strong; less than 3 ppm chlorine is likely too weak and will be ineffective against organisms in the water supply.

Hydrogen peroxide: Stabilized hydrogen peroxide is growing in popularity as a cleaning agent in drinker lines. The stabilizer keeps the sanitizer from converting to water and oxygen before it finishes the cleaning job. It works well on biofilms. It is non-corrosive to the drinker system and effective on bacteria, fungi, and viruses. It breaks down algae thoroughly to allow it to pass through nipple drinkers without causing the nipple to clog or stick.

Citric Acid: Commonly used in the past, new research has shown that citric acid may be giving biofilms a “food source”, making it an ineffective cleaning solution.

Tips:

Use the proper concentration and allow the solution the proper time to work. Too little and the cleaning will be ineffective and too much will result in quicker wear on equipment. Always follow manufacturer guidelines! Remember – not all cleaners are safe for use in drinking lines – check with your equipment manufacturer before trying a new chemical.

Clean the entire system – standpipes, regulators, and nipple drinkers. Leave no opportunity for biofilm to grow.

No two farms are the same. Document what works for your facility, in detail, and follow a regular cleaning regimen.

If you run any additives that could feed biofilm through the medicator, flush the water system immediately afterward.

If you do not know what the levels are from your water source, consider having a mineral analysis or bacterial analysis done to find out what is in it.

General Cleaning Procedure:

- Mix cleaning solution per manufacturer’s instructions

- Fill watering system with solution

- Allow solution to sit 1 -3 hours

- Flush system with plain water using high pressure

- Check filters, valves, and nipples for clogging from debris

- Adjust regulator pressure to normal operating pressure

Water quality is only part of the story. Drinker line height and Water Pressure also play key roles in ensuring fresh, available water.