VAL-CO products offer the best in production systems for poultry and swine.

Feeding

Feeding

Broiler chicken feeders by VAL-CO guarantee success in any broiler-rearing operation. The customizable systems give you your choice of feed pan, chick feeders, and feed delivery options to fit your own farming style. The FUZE Feed Pan regularly out-performs other feed pans in head-to-head feed trials. A variety of chick feeder options let you […]

Nesting

Nesting

Nesting systems give hens a place to lay their eggs for easy collection. Through research, experience, trial and error, we have developed a high-quality nesting experience for your breeder hens. The larger openings are more inviting to birds who enjoy a little privacy and the laying substrate is soft and pliable, to invite hens into […]

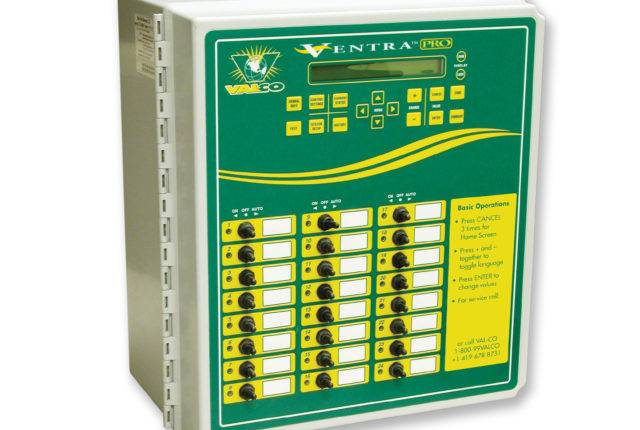

Whole House Controllers

Whole House Controllers

No modern farm system is complete without a controller to automate house systems. VAL-CO whole house controllers can run feed systems, control ventilation patterns, and monitor house temperatures to adjust heating and cooling requirements. Run variable speed fans, control egg belts, access house information remotely, and record and store data to review trends.

Biosecurity

Biosecurity

Biosecurity is the protection of health through avoidance of disease. More broadly, this includes the implementation of measures that reduce the risk of the introduction and spread of disease agents. Biosecurity comes in two different forms, bio-exclusion and bio-containment. Bio-exclusion is external biosecurity that combines all activities that prevent the introduction of disease to a […]